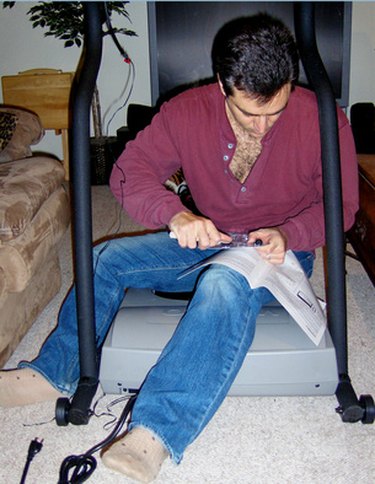

It is always best to check the manual for the machine you want to purchase a new belt for. The manual will have the most accurate measurements. Many belts become damaged or stretched after installation and the measurement you obtain will not always be the correct one. Replacing a smaller belt for a larger one can result in damage to the machine, the new belt or decreased operation of functionality of the machine itself. If the manual is not available, consider the condition of the belt before measuring and deciding on a replacement size.

Step 1

Stretch the conveyor belt out on a flat surface if not attached to a machine. Stretch a tape measure flat against the belt to record the length between the top and bottom portions. This will give you the length of the belt you need.

Video of the Day

Step 2

Measure the length of belt you need by recording the path of the belt in the machine you intend to use it in if the belt is damaged. This path will be the area in which the belt will travel while in use.

Step 3

Determine the width of the belt by measuring it from edge to edge. The width of the belt is important when purchasing a new belt. Having a belt that is too thin will result in more frequent and easier breaks.

Step 4

Record the length and thickness of the pulley that will hold the conveyer belt if the belt is already broken. This method will also help determine the width of the belt you will need.

Step 5

Purchase a belt that is an inch or two smaller than the measurement of the path. This will leave room for the belt to securely attach and stretch out a few inches while adjusting to the machine.

Video of the Day