Things You'll Need

Graphite

Silicon carbide

Silicon material

Glass

Aluminosilicates

High fire clay

Pottery wheel (optional)

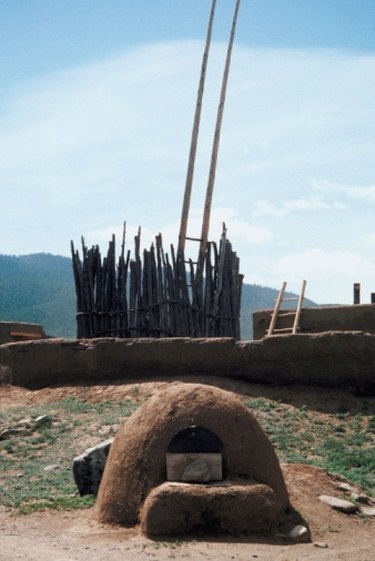

Kiln

Metal casters usually use a crucible that is made out of ferrous metal such as steel or cast iron. However, when these crucibles are placed into a direct air blast (usually a furnace) they are prone to oxidation and will eventually fail. To prevent your metals from being contaminated by an oxidized metal crucible, you can make your own clay graphite crucible that can better withstand heat.

Step 1

Mix up your graphite clay. There is no specific recipe for creating graphite clay for crucibles because all crucibles are used for melting different metals. You will have to come up with your own mixture of graphite, silicon carbide, silicon material, glass and aluminosilicates. For a basic crucible, you will require 30 to 50 percent (by weight) of flake graphite and 10 to 50 percent silicon carbide. Make sure you include high fire clay in your recipe so that your crucible can withstand the heat of the furnace.

Video of the Day

Step 2

Form the clay into a crucible shape using a pottery wheel or by pitching it into shape with your hands. A pottery wheel will give you more of a symmetrical shape.

Step 3

Fire the crucible for 7 hours at 2100 degrees Fahrenheit and allow it to cool overnight. Do not glaze the crucible.

Step 4

Heat the crucible slowly to prevent the crucible from experiencing thermal shock. Every time you use your crucible you will need to heat it slowly for a few hours to ensure it doesn't crack.

Tip

Creating the perfect crucible for your metal working purposes can take a lot of trial and error. Keep modifying your clay recipe until you get it just right.

Video of the Day